Sterile Processing

Your Guide To ANSI/AAMI ST108: Water for the Sterile Processing of Medical Devices

The Association for the Advancement of Medical Instrumentation (AAMI) has published a new standard that establishes the quality of water used to process reusable medical devices. The first standard of its kind, ANSI/AAMI ST108:2023, Water for the Processing of Medical Devices, was developed by nearly 120 subject matter experts under the guidance of the AAMI Sterilization Standards Committee.

The new standard, unlike the technical information report, provides clear requirements for every stage of medical device processing that encourages healthcare facilities to conform to the best practices for device processing water quality. ANSI/AAMI ST108 revises and replaces AAMI TIR:34:2014/(R)2021.

ANSI/AAMI ST108 outlines the essential criteria for water quality and steam purity essential for efficiently processing medical devices for patient use.

The new standard:

- Identifies the categories of water quality to be used during each stage of sterile processing.

- Provides risk analysis and establishes roles and responsibilities for processing facilities.

- Quantifies water quality given pH, microbial levels, and conductivity, as well as other properties.

- Establishes maintenance, monitoring, and quality improvement procedures for water treatment systems.

- Addresses emergency circumstances such as interruptions and boil water advisories.

The specifications of ANSI/AAMI ST108 for water quality create a path for enhanced patient outcomes and offer clear compliance benchmarks for healthcare facilities.

Hall’s Culligan Commercial Installs NuStream Filtration Systems

Hall’s Culligan Commercial installs the NuStream TIR 34/ST108 Sterile Processing water system. This system is designed to produce water that meets ANSI/AAMI ST108 water quality standards.

Features:

- US Department of Veteran Affairs PG-18-12 Design Guide Compliant.

- Pretreatment Chemical Injection Package with Integrated doser pumps.

- Professional Grade RO with Product Divert and Remote Alarm.

- Integrated CIP /Disinfection Pump and Tank For Entire System Disinfection.

- 75% Recovery for Water Conservation.

- 100-325 gallon cone bottom tank with a sealed lid and vent filter.

- 1” loop return with flow meter, pressure relief valve, and drain.

- Single or dual distribution pump packages are capable of 40 or 80 GPM at 30 PSI.

Hall’s Culligan Commercial installs the NuStream NuSurge SP – All In One Complete Water Treatment System. This system is designed to produce water that meets ANSI/AAMI ST108 water quality standards while occupying about one-fifth of the space required by traditional water treatment systems, without compromising on performance or efficiency.

Components:

- Carbon and Phosphate Filter

- Particulate Filter

- RO Membrane

- Deionizer Cartridge

- Ultra-Violet System

- CMF Validated Filter

- Pumps 240, Single Phase

- Storage Tank (Sold Separately)

What Makes Hall’s Culligan Commercial Unique

When Was ANSI/AAMI ST108 Established and When Does it Need to be Implemented?

ST108 became an ANSI standard on August 4, 2023. Many hospitals and medical facilities are currently preparing to implement the new standards. Specific expectations for hospitals will likely become clearer in early 2024 after AAMI finishes and publishes its “Guidance on Healthcare Implementation and Use of AAMI ST108”. Medical facilities that perform surgical procedures will need to coordinate new system installation with a water treatment specialist and a mechanical contractor. Contact us today for nationwide sales and service.

What Changed from the Old Standard to the New Standard? (AAMI ST108 vs TIR34)

ANSI/AAMI ST108 revises and supersedes any information highlighted in the TIR34. While ST108 includes several aspects covered in TIR34, a significant difference lies in their classification.

ST108 is designated as a standard, whereas TIR34 is solely a technical information report (TIR). In this updated standard introduces a few distinct modifications:

- Establishing a water management team

- Revising acceptable water quality attributes, categories, and measurements

- Offering improved directives on designing and implementing water treatment systems

1) Establishing a Water Management Team

ST108 recognizes the significant task of meeting its water quality standards and proposes a helpful solution: forming a dedicated water management team. This team, defined with specific roles and responsibilities, is tasked with developing, implementing, and documenting the water management program to meet local regulations and standards.

2) Revising Acceptable Water Quality Attributes, Categories, and Measurements

While TIR34 only focused on microbial levels and inorganic/organic contaminants, ST108 incorporates an additional 3 characteristics, including physical appearance, total alkalinity, and temperature. These characteristics are accompanied by expanded water quality metrics across three categories: utility, critical, and steam.

3) Improved Directives on Designing and Implementing Water Treatment Systems

While TIR34 focused on water quality metrics and components of such systems, ST108 offers more detailed guidance on how to utilize various technologies to meet water quality standards for both utility and critical water. This expanded guidance serves as a starting point for facilities designing their water treatment systems.

Culligan’s Tips For Implementation of AAMI ST108

- Avoid The Dead-Legs – it’s important to choose the right engineering firm, understand the dangers of outdated piping designs, and adhere to pipework guidelines to avoid bacteria and endotoxin pitfalls.

- Sample Points Matter – emphasize clear specs on sample points in designs to ensure future expenses are avoided.

- Navigate Utility Water – understand the challenge of meeting Utility Water Standards, especially with underground water sources. Develop a strategy for redesigning water feeds to meet standards.

- Faucets as Bacteria Traps – Our experience has shown that faucets present bacteria challenges, so choose your faucet wisely.

- Have Clear Instructions & Plenty of Space – There is need for ample space in water rooms, inspired by Annex F. Know the importance of design considerations for equipment and technician space.

- Putting Off Steam – The requirement of quarterly steam condensate testing is emphasized in ST108. Remind your water management team of these new standards and adjustments.

- Buyer Beware: Know The Detail – It’s important someone has an understanding of details when upgrading the systems. Place an emphasis on studying and annotating the ST108 manual.

To learn more about these insights for success, check out ST108 Specialist Allen Clouse’s blog (from LinkedIn) HERE.

Sterile Processing: Why is Water so Important?

Sterile processing is the process of cleaning, inspecting, disinfecting, and sterilizing medical devices used during surgical procedures. Water impurities can have a wide range of adverse effects such as:

- Damage/corrosion, biofilm buildup, and increased microbial load or endotoxin content on medical devices

- Decreased efficacy of cleaning agents and degradation of the processing equipment

- Toxicity, infection, and adverse reactions in patients

- Health and environmental safety risks for medical personnel

To address problems stemming from water impurities, the solution lies in sterilizing medical equipment with “critical water”.

Critical water is extensively treated to eliminate unwanted minerals, contaminants, and microorganisms, as well as organic and inorganic materials. It is specifically recommended for medical instruments that come into contact with the bloodstream or other sterile regions of the body.

Categories of Recommended Levels of Water Quality for Medical Device Processing

ANSI/AAMI ST108:2023 establishes three classifications of water quality for the processing of medical devices.

- Utility water – Water that comes from the tap and requires further treatment.

- Used for washing, flushing, and rinsing of medical devices

- Critical water – Water that is extensively treated to eliminate unwanted minerals, contaminants, and microorganisms, as well as organic and inorganic materials.

- Used for final rinse of steam generation

- Steam – Water that is heated with a boiler/steam generator until it changes to vapor.

- Used for sterilization of medical devices

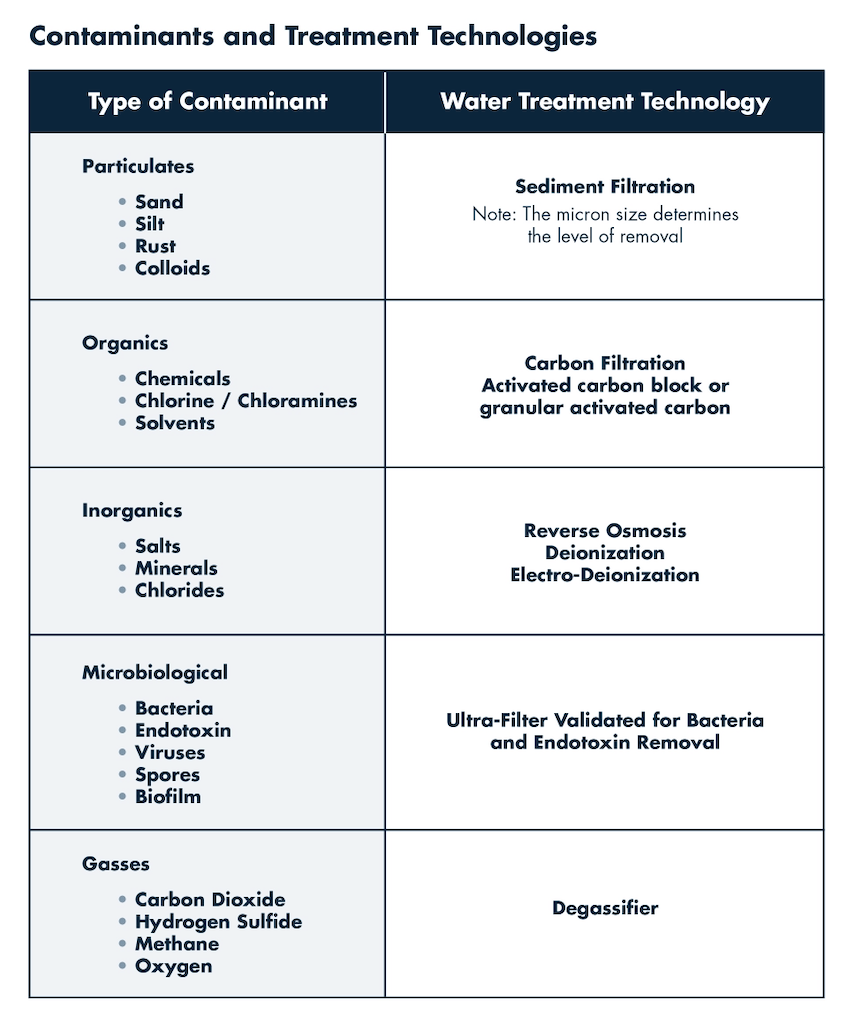

Types of Water Contaminants and Water Treatment Technologies

The table provided below showcases the primary categories of contaminants along with the appropriate water treatment methods utilized for their mitigation or removal.

How Should Sterile Processing Departments and Facilities Implement AAMI ST108?

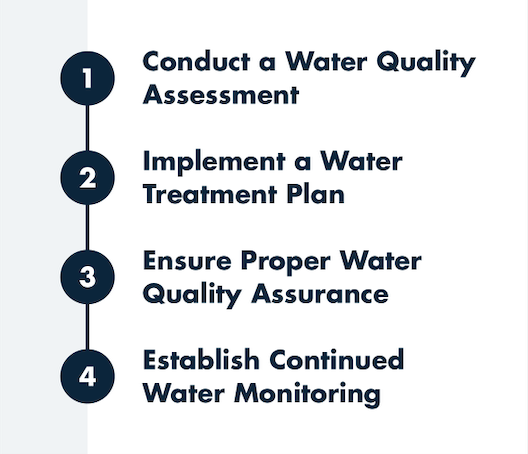

To achieve water quality, sterile processing departments, and hospital facilities teams should follow the four steps:

- Tap water sourced from a public utility should undergo analysis by accredited facilities specializing in water quality assessment. This evaluation determines if water treatment is necessary and, if so, identifies the appropriate treatment method.

- If treatment is required, personnel must execute treatment procedures to deliver the required water quality essential for medical device processing.

- Regular audits of process water in medical device reprocessing areas are essential to verify the use of appropriate water quality for each device. Adjustments to water treatment methods should be made if discrepancies are identified.

- Routine monitoring procedures should be established to frequently assess the quality of treated water used for medical device reprocessing.

What Happens if Water Treatment Systems Aren’t Implemented Properly or on Time?

Here is an example: after sterilizing a pack of surgical instruments, the team conducts cleanliness testing. Should it fail, the facility suspends surgeries for the day. Surgery resumes only when the water quality in the sterilization system meets minimum standards. Even a one-day setback costs any facility an extremely high amount of time and money.

Working with an experienced, reputable water treatment provider like Hall’s Culligan Commercial is one of the best forms of defense against failed test results and surgery shutdowns.

“Facility shutdowns caused by poor water quality result in hundreds of thousands in lost revenue and potential long-term damage to the facility’s reputation.”

What Facilities Are Impacted? How Do the New Standards Affect Facility Managers?

- Major medical centers

- Hospitals

- Ambulatory surgical centers

- Doctor’s offices offering outpatient or same-day surgery

The introduction of the new ST108 standards will have a direct effect on the responsibilities of facility managers. Any facility that processes surgical instruments will be required to uphold higher standards of excellence than ever before.

Choose Hall’s Culligan Commercial – Culligan Commercial Consultants – Experts You Can Trust.

Hall’s Culligan Commercial brings local expertise in water treatment with a national reach in sales and service. We have experts ready to help in your area, and are always just a phone call and quick drive away.

With a focus on meeting ANSI/AAMI ST108:2023 standards, our tailored solutions provide reliable water quality and quantity essential for cleaning, rinsing, disinfecting, and sterilizing medical devices. Our comprehensive package includes pre-treatment, reverse osmosis, deionization, and post-treatment with endotoxin filtration to promote compliance with industry regulations.

We provide design assistance for utility water and critical water recirculating loops, prioritizing patient well-being and the longevity of medical equipment. Our custom-sized systems are adept at fulfilling sterile processing requirements efficiently. Additionally, our services extend beyond the initial sale, encompassing extended service agreements and testing services to provide ongoing support and performance optimization.

Contact Hall’s Culligan Commercial today to arrange your complimentary on-site evaluation and consultation! Our services extend nationwide, serving customers throughout the US.